Our second hand robots

Press tending

-

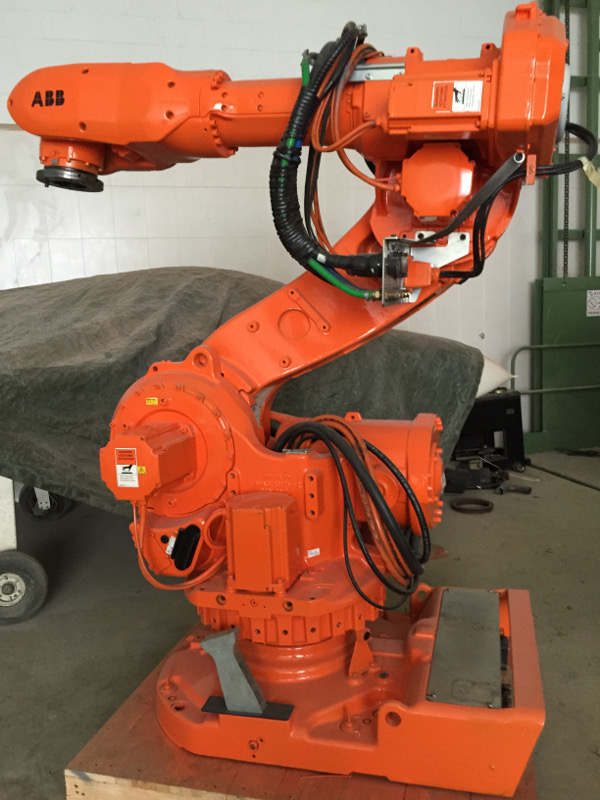

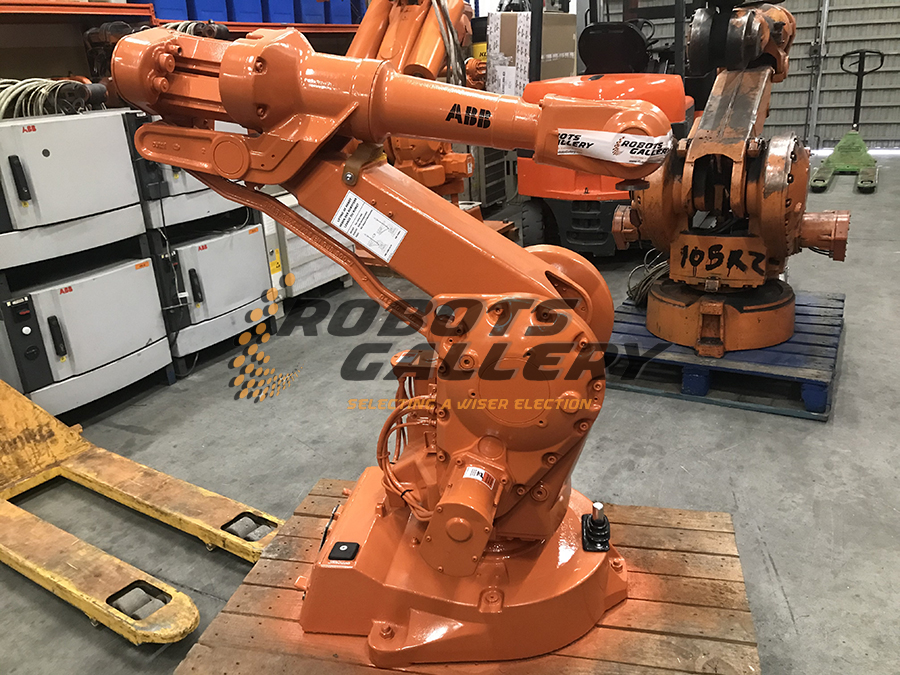

ABB

IRB 6640 IRC5 M2004 235 kg payload

Arm reach 2,55 m -

ABB

IRB 6400R S4CPlus REX

Arm reach 2,50 m -

ABB

IRB 6600 S4CPlus M2000

Arm reach 2,80 m -

ABB

IRB 6600 IRC5 M2004

Arm reach 2,55 m -

ABB

IRB 6640 IRC5 M2004

Arm reach 2,55 m -

ABB

IRB 2400/16 S4CPlus M2000

Arm reach 1,55 m -

ABB

IRB 6640 Foundry Plus

Arm reach 2,55 m -

ABB

IRB 6400 S4C M98

Arm reach 2,40 m -

ABB

IRB 6640 IRC5 M2004 3200 mm arm reach

Arm reach 3,20 m -

ABB

IRB 6650 Shelf S4CPlus M2000

Arm reach 3,50 m -

ABB

IRB 2400/10 IRC5 M2004

Arm reach 1,50 m -

ABB

IRB 6400R S4CPlus REX 3,00 m / 100 kg

Arm reach 3,00 m -

ABB

IRB 4400/60 IRC5

Arm reach 1,96 m -

ABB

IRB 6400 Shelf M2000

Arm reach 2,90 m -

ABB

IRB 4400 S4CPlus M2000

Arm reach 1,95 m -

ABB

IRB 7600 IRC5 325 kg 3100 mm

Arm reach 3,10 m -

ABB

IRB 2400-16 IRC5

Arm reach 1,50 m -

ABB

IRB 6640 IRC5 M2004 205 kg payload

Arm reach 2,75 m -

Fanuc

R2000i/165F RJ3i model B

Arm reach 2,65 m -

Fanuc

M710iC/70

Arm reach 2,05 m -

Fanuc

R2000iB 210F R30iA

Arm reach 2,66 m -

Fanuc

LR Mate 200iC R30iA

Arm reach 0,70 m -

Fanuc

Arc Mate 120iB RJ3iB

Arm reach 1,67 m -

Fanuc

R2000i/165F RJ3iB mounted on linear track

Arm reach 2,65 m -

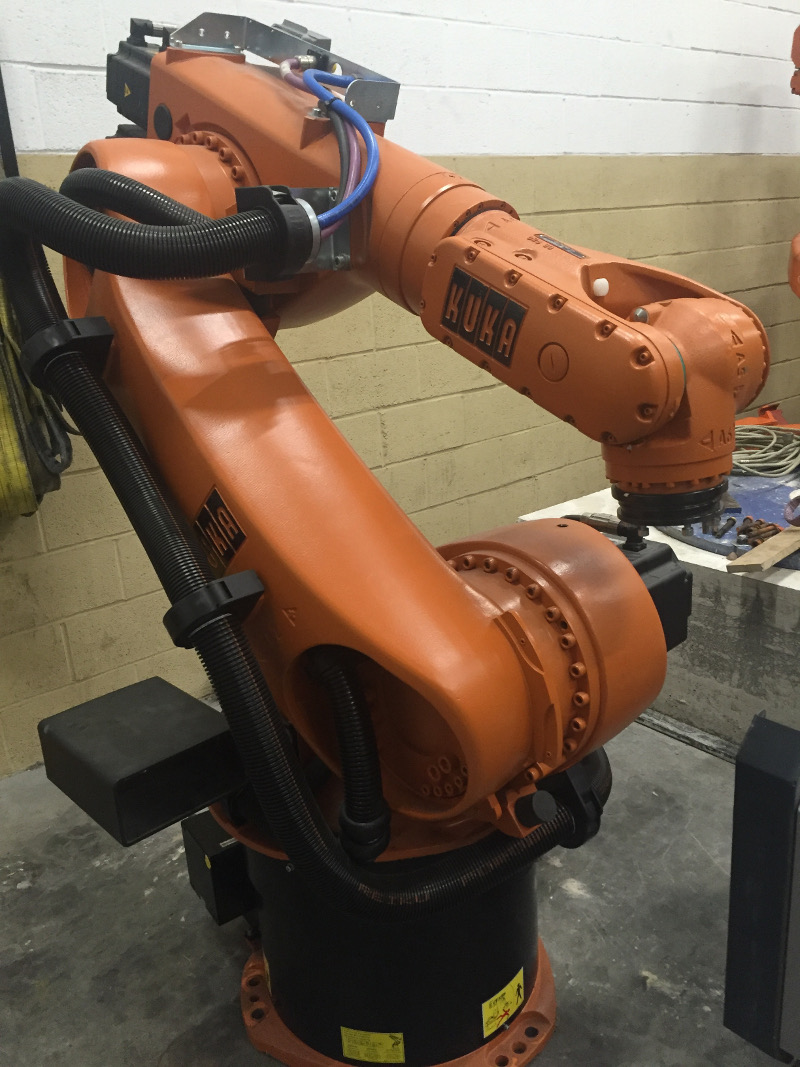

KUKA

KR 30-3 KRC2 Ed05

Arm reach 2,03 m -

KUKA

KR 350/240

Arm reach 2,94 m -

KUKA

KR 60/3 KRC2 Ed05

Arm reach 2,03 m -

KUKA

KR 150-2 Series 2000 KRC2

Arm reach 2,70 m -

KUKA

KR 210-2 Series 2000 KRC2

Arm reach 2,70 m -

KUKA

KR 125 - KR150

Arm reach 2,80 m -

KUKA

KR 210 KRC2 Ed05

Arm reach 2,70 m -

.jpg)

KUKA

KR 210L150-2 2000

Arm reach 3,10 m -

.jpg)

KUKA

KR 210L180-2 2000

Arm reach 2,90 m -

KUKA

KR 200L170-2 Comp

Arm reach 2,60 m -

.jpg)

KUKA

KR 360-2 KRC2 Ed05

Arm reach 2,82 m -

KUKA

KR 200L140-2 Comp

Arm reach 2,80 m -

Yaskawa - Motoman

UP 165

Arm reach 2,65 m -

Yaskawa - Motoman

MH 180

Arm reach 2,70 m -

Kawasaki

ZX 165U

Arm reach 3,23 m

Press tending

The press tending manipulators robots extract pieces from one press and place it in the next. Due to the way of gripping the pieces and their movement, it may be necessary to reorient the displaced part, which is why the use of 6-axis robots is common.

The lines of presses are destined to the deformation of pieces of big dimensions. They are usually composed of several presses, placed in line and powered by robots. The robots perform the function of the intermediate transport of the pieces between presses.

Industrial robots used in the printing sector are used for the manipulation of formats to feed the presses, due to the flexibility and the great precision and speed at which they can work.

The great advantage of the feeding of presses with industrial robots of occasion, lies in the great capacity of adaptation that they have to the change of pieces or form of work depending on the productive needs.

In press lines there are robots in the header to feed the start of line, robots between press and press and at the end of the lines to remove the piece already finished and proceed to its palletizing.

It’s tending to automate the entire process as much as possible, from machining, to process control, to the transportation of parts between presses, so that the parts are completely finished and verified, without any manual intervention. In this way, precision and repeatability are obtained with a high level of productivity.

The parts to be stamped are of considerable size and weight, for this reason their handling is automated by means of industrial robots.

When the complexity of the formats or parts to be manipulated is high, an application is developed by means of industrial robots that satisfy the needs of the process. These can be for unstacking of formats in press lines, for the transfer of the formats between the presses or for the stacking of pieces once they leave the press.