Our second hand robots

Assembly of parts

-

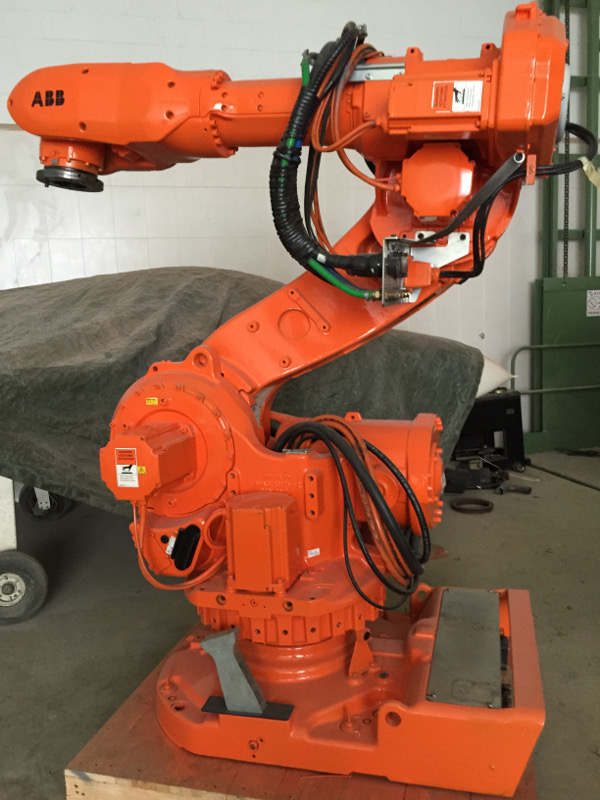

ABB

IRB 6640 IRC5 M2004 235 kg payload

Arm reach 2,55 m -

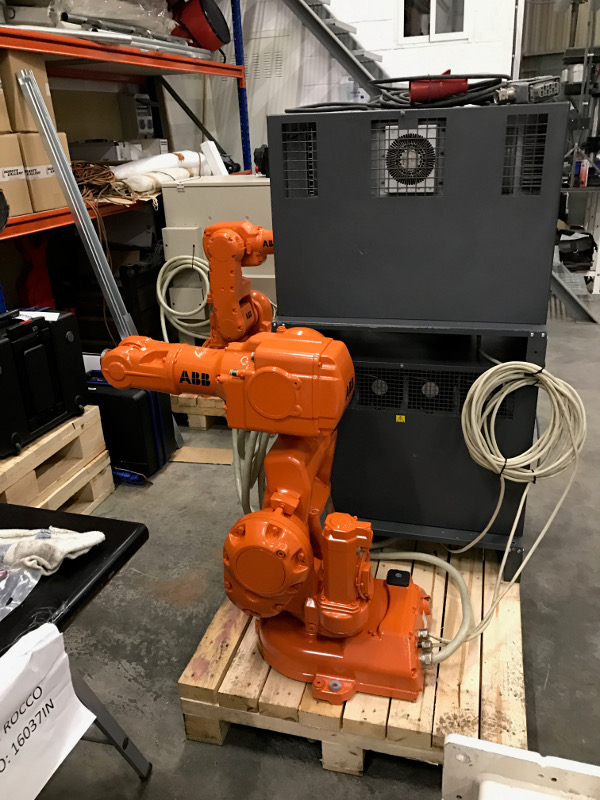

ABB

IRB 6400R S4CPlus REX

Arm reach 2,50 m -

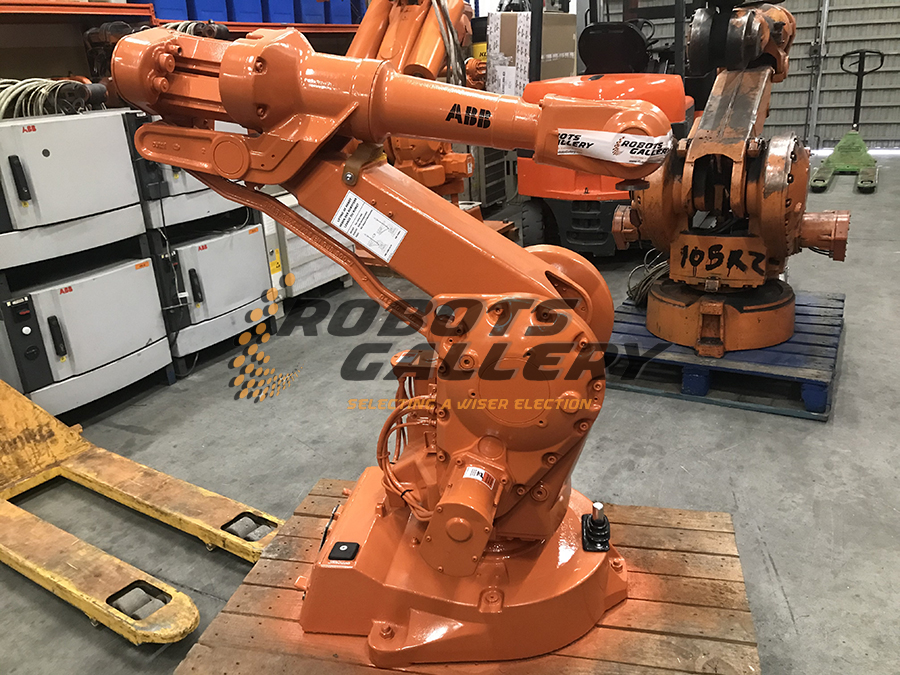

ABB

IRB 1400 S4C M98A

Arm reach 1,44 m -

ABB

IRB 1400 S4CPlus M2000

Arm reach 1,44 m -

ABB

IRB 6600 S4CPlus M2000

Arm reach 2,80 m -

ABB

IRB 6600 IRC5 M2004

Arm reach 2,55 m -

ABB

IRB 6640 IRC5 M2004

Arm reach 2,55 m -

ABB

IRB 2400/16 S4CPlus M2000

Arm reach 1,55 m -

ABB

IRB 6640 Foundry Plus

Arm reach 2,55 m -

ABB

IRB 6400 S4C M98

Arm reach 2,40 m -

ABB

IRB 6640 IRC5 M2004 3200 mm arm reach

Arm reach 3,20 m -

_0.jpg)

ABB

IRB 2400L S4CPlus M2000

Arm reach 1,80 m -

ABB

IRB 6650 Shelf S4CPlus M2000

Arm reach 3,50 m -

ABB

IRB 2400/10 S4C M98A

Arm reach 1,50 m -

ABB

IRB 140 IRC5 M2004

Arm reach 0,81 m -

ABB

IRB 140 S4CPlus M2000

Arm reach 0,81 m -

ABB

IRB 1600 IRC5 M2004

Arm reach 1.450,00 m -

ABB

IRB 2400/10 IRC5 M2004

Arm reach 1,50 m -

ABB

IRB 6400R S4CPlus REX 3,00 m / 100 kg

Arm reach 3,00 m -

ABB

IRB 4400/60 IRC5

Arm reach 1,96 m -

ABB

IRB 6620 IRC5 M2004

Arm reach 2,20 m -

ABB

IRB 6400 Shelf M2000

Arm reach 2,90 m -

.jpg)

ABB

IRB 1600iD IRC5 M2004 Multi move

Arm reach 1,50 m -

ABB

IRB 2400/10 S4CPlus M2000

Arm reach 1,50 m -

ABB

IRB 4400 S4 M94-M96

Arm reach 1,95 m -

ABB

IRB 4400 S4CPlus M2000

Arm reach 1,95 m -

ABB

IRB 7600 IRC5 325 kg 3100 mm

Arm reach 3,10 m -

ABB

IRB 2400-16 IRC5

Arm reach 1,50 m -

ABB

IRB 6640 IRC5 M2004 205 kg payload

Arm reach 2,75 m -

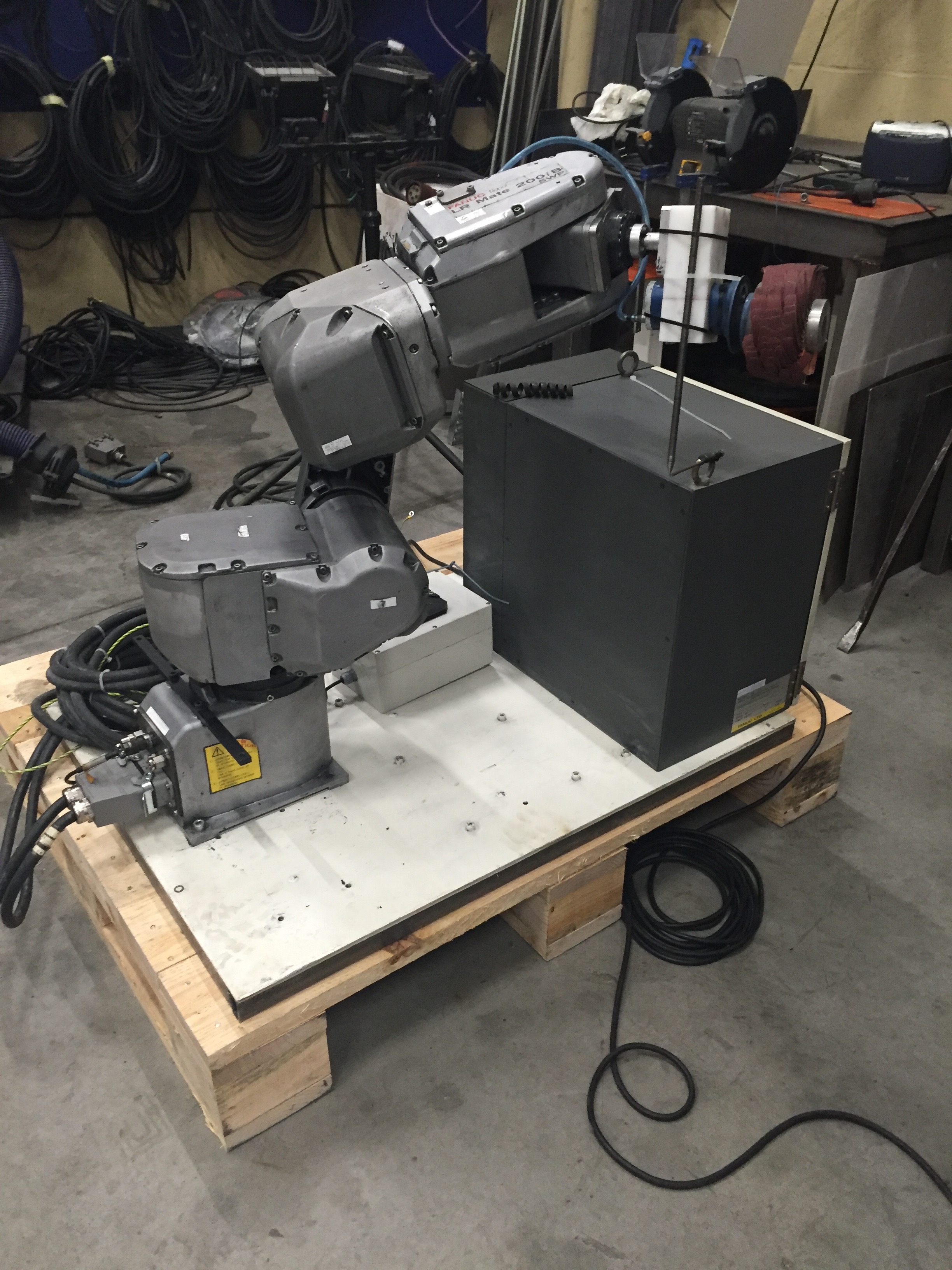

Fanuc

R2000i/165F RJ3i model B

Arm reach 2,65 m -

Fanuc

LR Mate 200iB 5WP

Arm reach 0,70 m -

Fanuc

M710iC/70

Arm reach 2,05 m -

Fanuc

R2000iB 210F R30iA

Arm reach 2,66 m -

Fanuc

LR Mate 200iC R30iA

Arm reach 0,70 m -

Fanuc

Arc Mate 120iB RJ3iB

Arm reach 1,67 m -

Fanuc

LR Mate 200iD

Arm reach 0,72 m -

Fanuc

S420iF RJ2

Arm reach 2,40 m -

Fanuc

M16iB R30iA

Arm reach 1,66 m -

Fanuc

M710iC/50 R30iA

Arm reach 2,05 m -

Fanuc

R2000i/165F RJ3iB mounted on linear track

Arm reach 2,65 m -

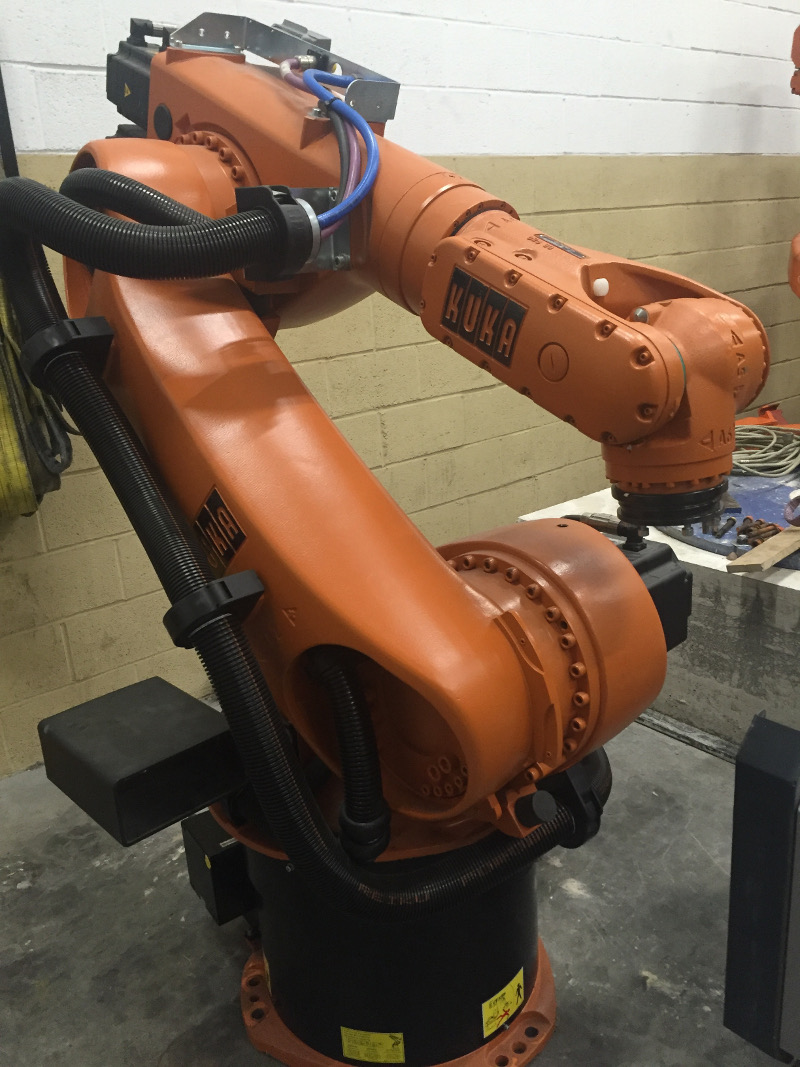

KUKA

KR16

Arm reach 1,61 m -

KUKA

KR 30-3 KRC2 Ed05

Arm reach 2,03 m -

KUKA

KR 350/240

Arm reach 2,94 m -

KUKA

KR 60/3 KRC2 Ed05

Arm reach 2,03 m -

KUKA

KR 150-2 Series 2000 KRC2

Arm reach 2,70 m -

KUKA

KR 210-2 Series 2000 KRC2

Arm reach 2,70 m -

KUKA

KR 125 - KR150

Arm reach 2,80 m -

KUKA

KR 210 KRC2 Ed05

Arm reach 2,70 m -

.jpg)

KUKA

KR 210L150-2 2000

Arm reach 3,10 m -

.jpg)

KUKA

KR 210L180-2 2000

Arm reach 2,90 m -

KUKA

KR 200L170-2 Comp

Arm reach 2,60 m -

.jpg)

KUKA

KR 360-2 KRC2 Ed05

Arm reach 2,82 m -

KUKA

KR 200L140-2 Comp

Arm reach 2,80 m -

Yaskawa - Motoman

UP 165

Arm reach 2,65 m -

Yaskawa - Motoman

MH 180

Arm reach 2,70 m -

Scara

Sony SRX-611 Scara

Arm reach 0,60 m -

Kawasaki

ZX 165U

Arm reach 3,23 m

Assembly of parts

High accuracy and repeatability are often required for these applications.

Sometimes the installation of sensors can be required to measure other factors, such as the force exerted on each one of the different components and a more complex control of the trajectories.

The robots used for assembly of parts perform automated tasks in industrial manufacturing. These used robots carry out tasks based on programmed movements provided with the necessary tools to perform their tasks, such as the placement of parts in an assembly line. The robots used for assembly are used mainly in manufacturing processes that require excessively repetitive tasks, that use hazardous materials or that involve unsafe conditions.

The robots for assembling parts are machines designed to perform different repetitive tasks at high speeds. They are very useful in the production process, in the packaging chains, etc. Tasks that are streamlined and maximized with used robots, can be found in any industry.

Many assembly processes have been automated using special machines that work with great precision and speed. However, the current market requires very flexible systems, which allow introducing frequent changes in products with minimal costs. For this reason the industrial robot used has become in many cases the ideal solution for assembly automation.

In particular, the used robot solves correctly many applications of assembly of small parts in mechanical or electrical assemblies.

The robots used in the assembly require, in any case, a high precision and repeatability, not being required to handle large loads.

Used 6-axis robots can solve many of these applications with sufficient effectiveness.

In this way, assemblies whose automated assembly would be unaffordable with their initial design, can be assembled in a competitive way by means of the use of used robots.